10/03/2023

Need an IP67 Switch? Begin by Asking Yourself These Questions

In factories, tunnels, agriculture, and even car washes, Ethernet switches facilitate the connection of essential telemetry to the network, enabling data collection and communication. Choosing the right Ethernet switch in such environments often comes down to a choice between IP classifications. The question then often arises: do I need an IP20 or IP67 switch? Both options serve the same purpose but offer different advantages and disadvantages to consider.

An IP20 switch is typically installed in a switch cabinet and is considered touch-safe (users do not come into contact with hazardous or live parts). Additionally, it prevents large dust particles from entering.

With an IP67 switch, you can place Ethernet systems directly at a machine, process, or factory floor without the need for a separate cabinet. This allows you to remotely configure, manage, and monitor the connected machinery and equipment. Consequently, you do not need to install long cables or special enclosures to house the switch and power supply.

Due to several factors, IP67 switches are sometimes considered the best option for Ethernet switches in the automotive industry. But does your factory really need an IP67 switch? Would an IP20 switch work just as well?

1. Is there moisture or frequent washing and rinsing involved

Water plays a significant role in many production processes, being utilized in various stages of a production or assembly line.

These applications may include:

- Paint booths where water serves as a filtering medium;

- Rinsing of products;

- Metal finishing operations;

- Agricultural and horticultural equipment requiring regular; cleaning with water

- Bodywork washing stations where cars are cleaned before leaving the factory;

- Rain test chambers ensuring waterproofing.

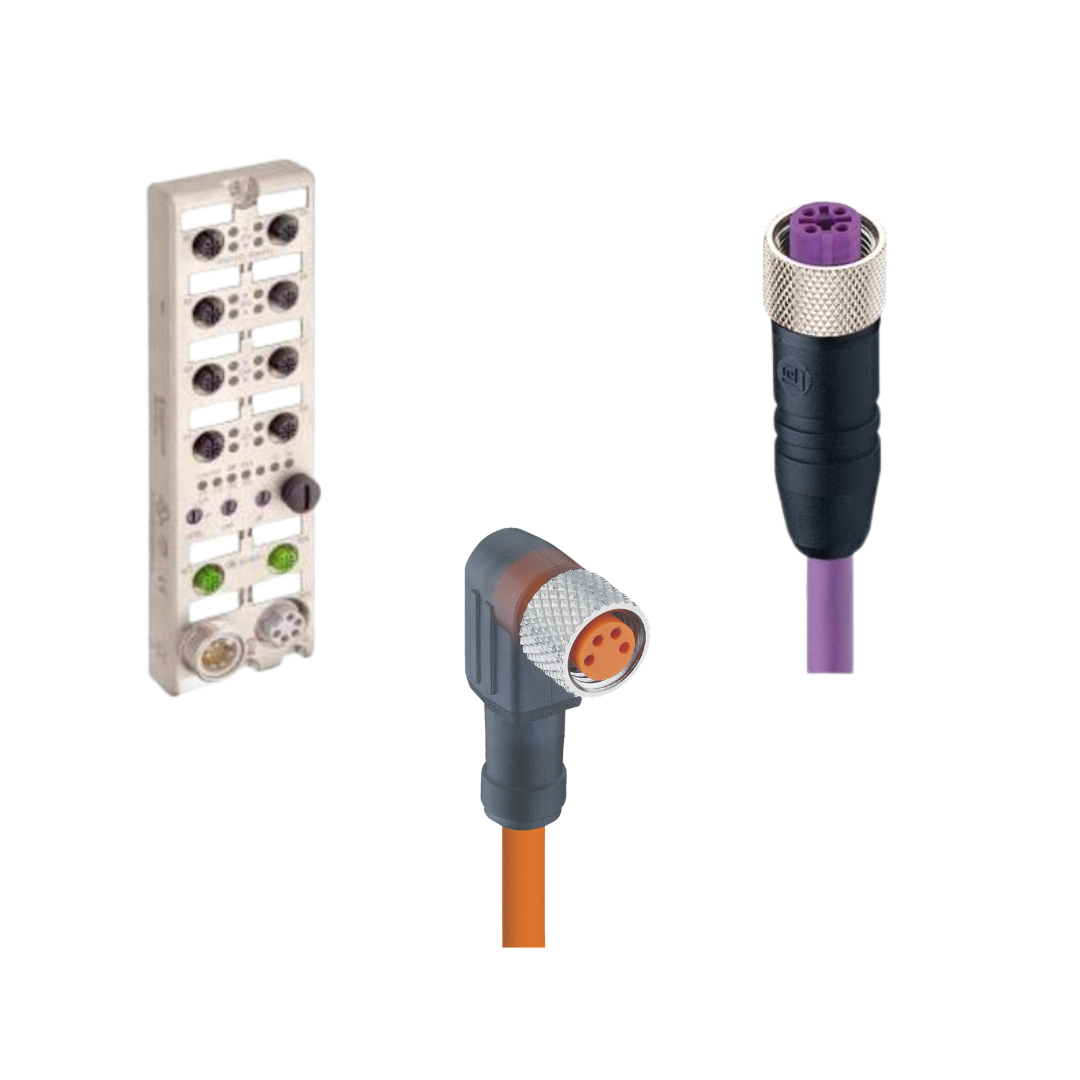

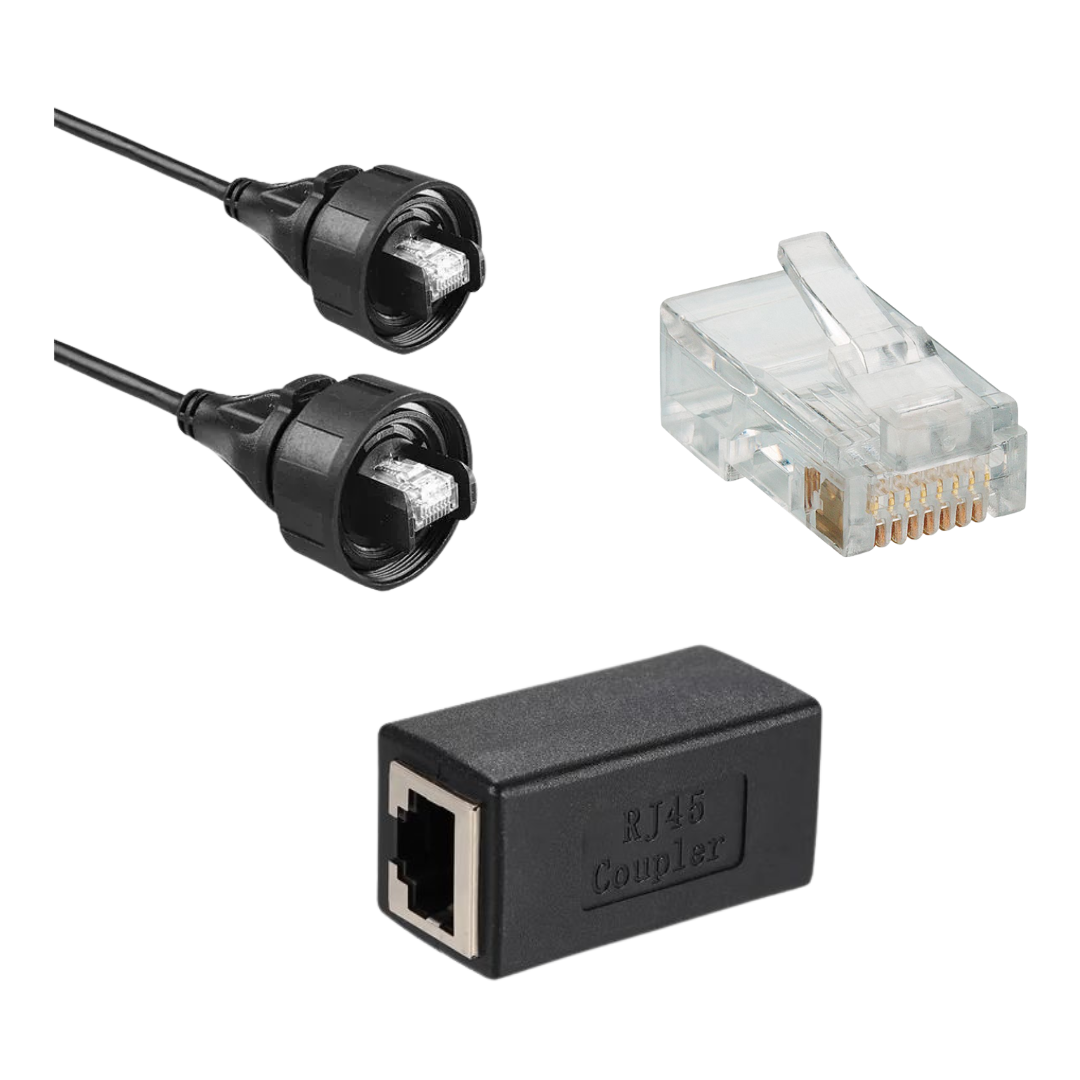

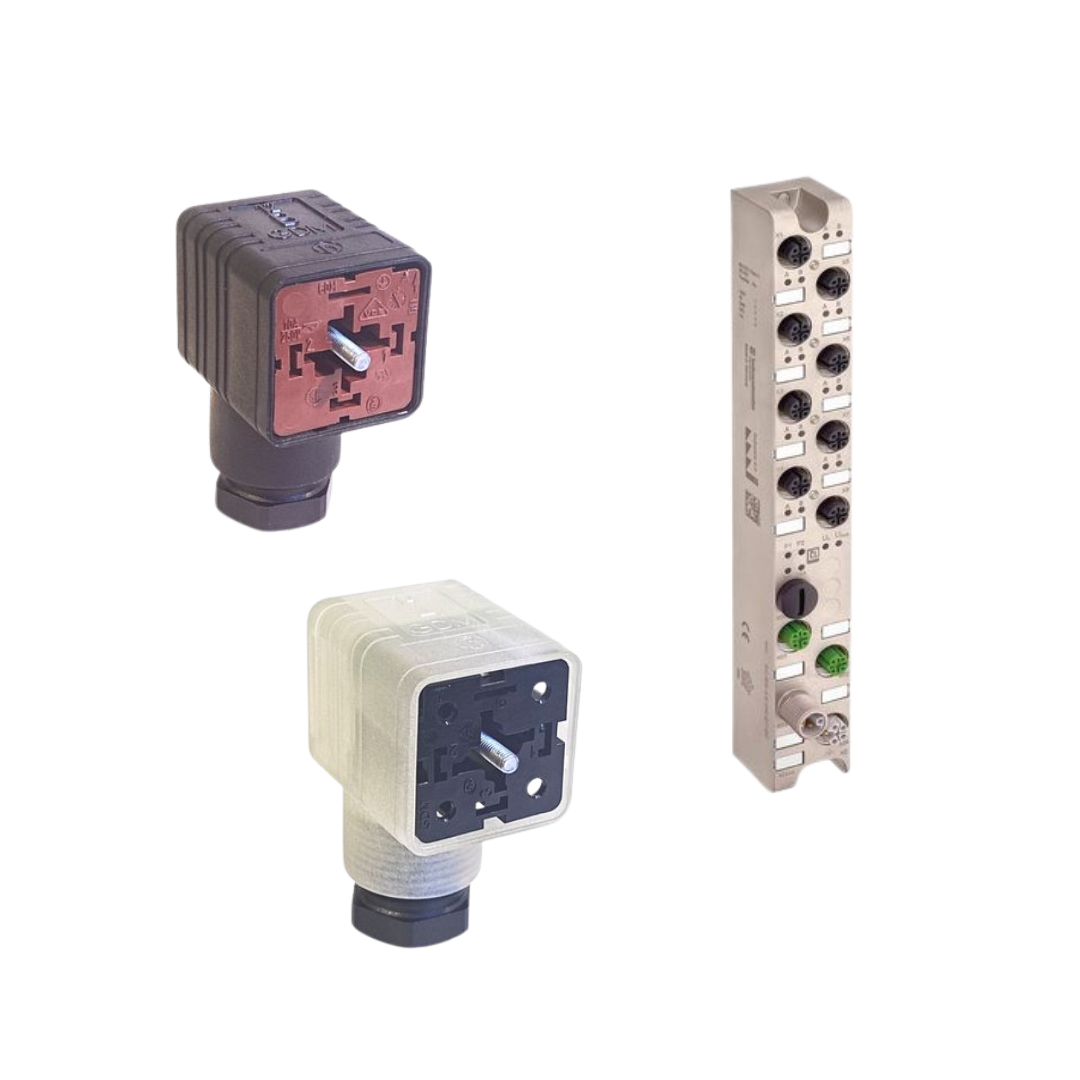

If an Ethernet switch is deployed in a production area with a significant presence of water, it must be protected against water ingress. To safeguard against water ingress, IP67 Ethernet switches utilize M12 connectors instead of the RJ45 connectivity found in IP20 switches.

2. Is there dust and dirt present?

In many environments where the production line is operated by employees, dust is a common occurrence. When there is a significant presence of dust in the production environment, it's essential to safeguard Ethernet switches against dust ingress.

The following applications often generate considerable amounts of dust:

- Cutting;

- Grinding;

- Machining;

- Plastic processing;

- Rubber production;

- Stamping;

- Welding.

An IP20 switch prevents the ingress of dust particles larger than 12 mm in diameter. Conversely, an IP67 switch is deemed completely dustproof and offers full protection against dust and other particles.

3. Is a clear line of sight necessary?

- to support communication?

- to determine when assistance is needed?

- to monitor equipment for alerts?

- to maintain productivity?

- to ensure compliance with quality standards?

An IP67 switch can be installed directly on machines, outside of a protective enclosure. This ensures that they do not obstruct the view of production lines or impede visual verification.

4. Do protective switch cabinets require more space?

Real estate expenses can be significant when operating a factory. Maximizing the space utilized by cabinets can help optimize the factory floor area, leading to reductions in labor and material costs.

If you're seeking to optimize factory floor space, an IP67 Ethernet switch can be a solution. Mounting the switch outside the cabinet and directly onto the machine also results in shorter cable runs, further reducing labor and material costs.

5. Is maintenance an issue?

Installation regulations in many countries dictate that electricians must wear personal protective equipment that does not conduct electricity before working in a live cabinet. If an IP20 switch is situated inside the cabinet, electricians require access to it.

IP67 switches eliminate this requirement and the risk of arc flashes. By mounting the Ethernet switch outside the switch cabinet, electricians spend less time working in a cabinet, thereby enhancing safety.

Making the right choise

If the aforementioned factors are crucial for your production environment, then an IP67 switch might be the optimal choice. However, if these factors are not significant, an IP20 switch can offer a practical and cost-effective solution.

For factories and environments necessitating IP67 Ethernet switches, Lumberg Netherlands provides the Belden OCTOPUS IP67 Ethernet switch along with corresponding M12 connector and cable sets. These enable (auto)factories to install reliable, trouble-free networks in demanding conditions.

Source: Belden